- FRC Robot Programming

- Preface

- 1. Introduction

- 2. Robot Components

- 3. Learning C++

- 4. Robot Programming

- 5. To Infinity and Beyond

- 6. Bibliographies

General Hardware Overview

This section presents the 2015 control system general hardware. This document is very important for any member of the engineering area of your team, as it summarizes most of the components that your robot will make use of.

Some of the contents of this document come from the official WPILib documentation.

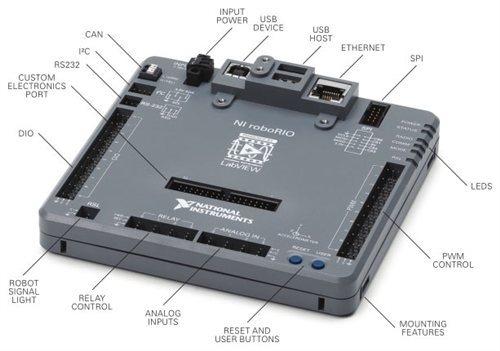

➠ The roboRIO

The roboRIO is the main robot controller used for FRC robots. It loads the user code during startup and manages attached devices with your code.

Detailed information on the roboRIO can be found in the roboRIO User Manual.

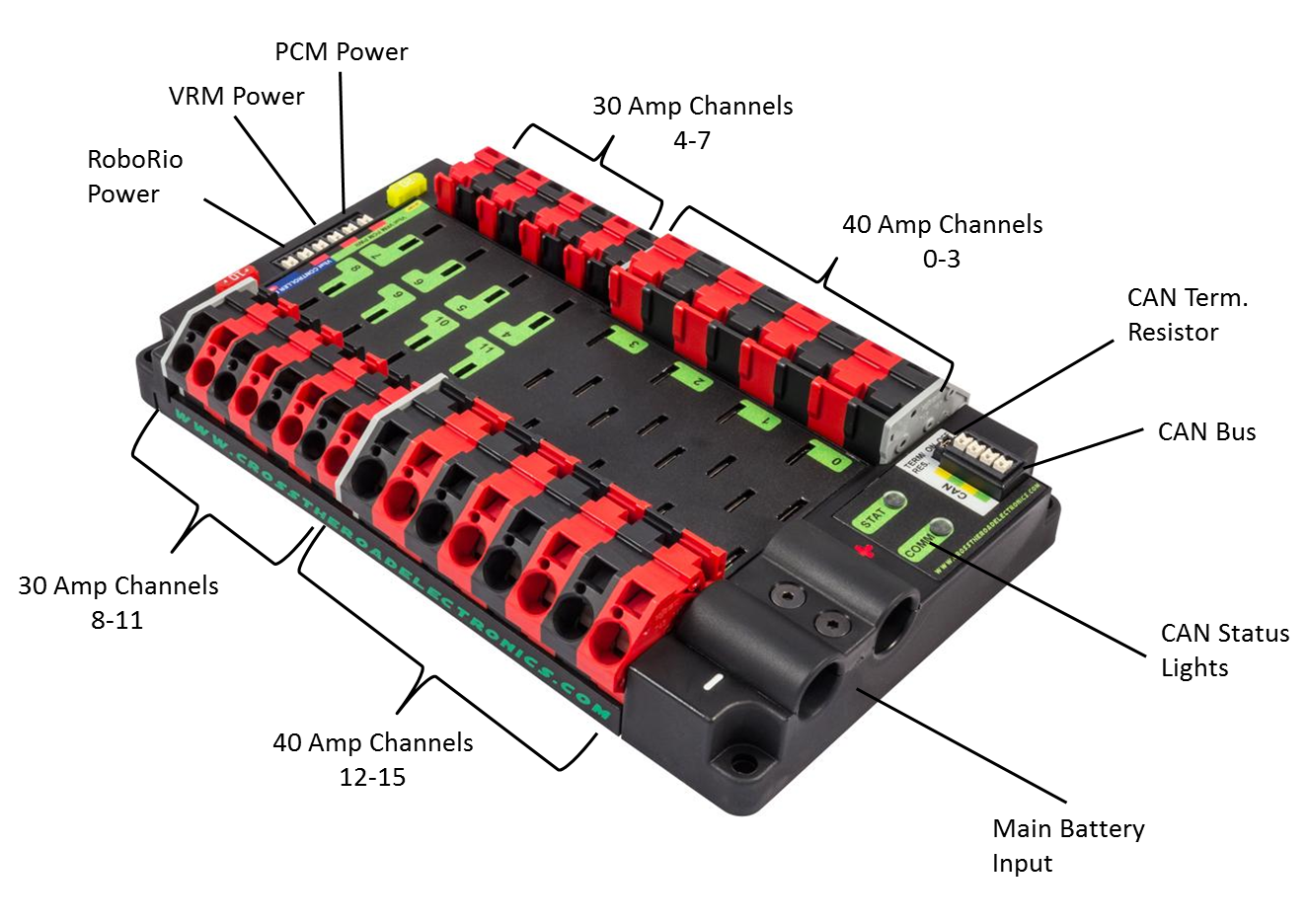

➠ The Power Distribution Panel (PDP)

The Power Distribution Panel (PDP) is designed to distribute power from a 12VDC battery to various robot components. In the case of a short, the PDP will trip the corresponding breaker automatically.

For more detailed information, see the PDP User Manual.

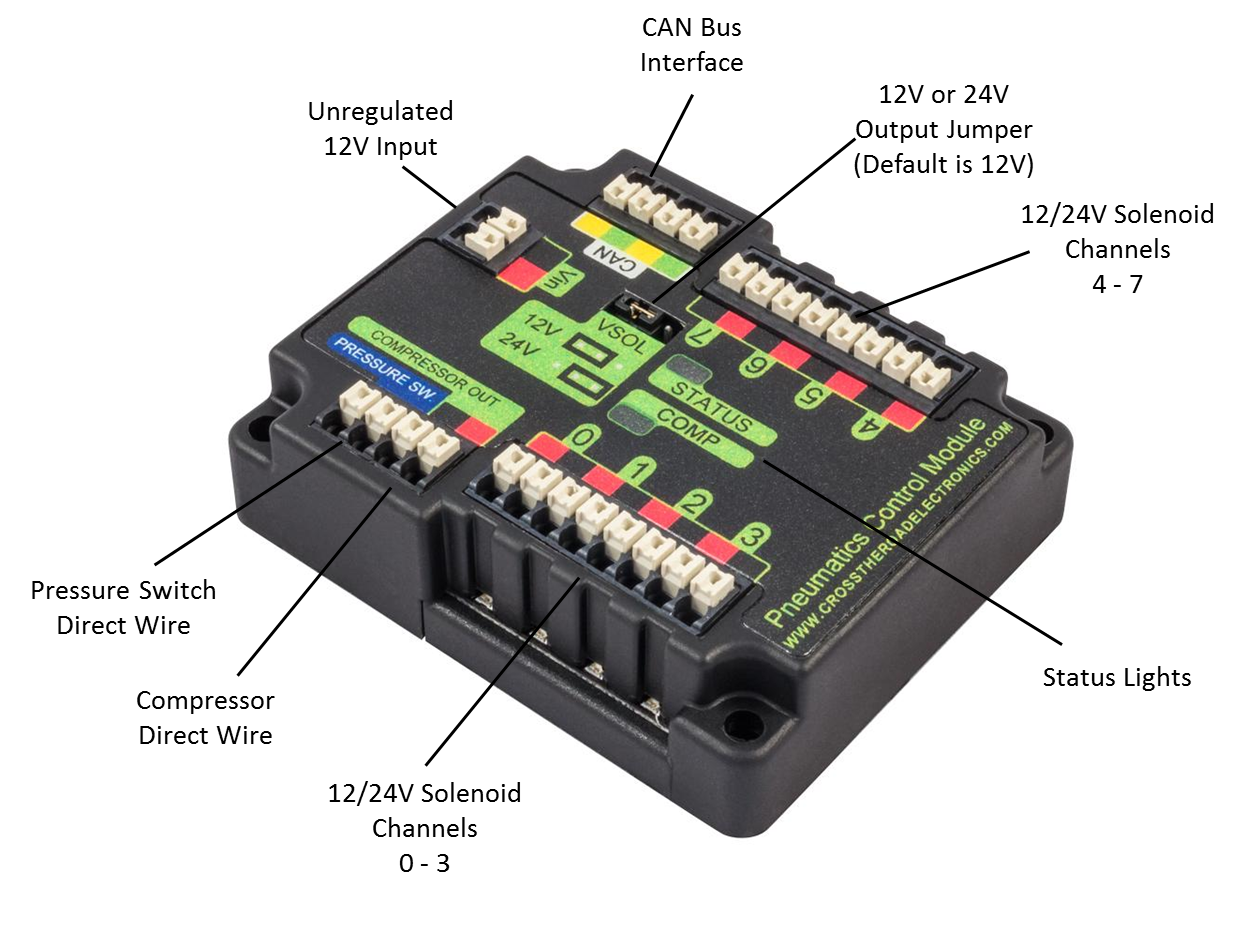

➠ Pneumatics Control Module (PCM)

The PCM is a device that contains all of the inputs and outputs required to operate 12V or 24V pneumatic solenoids and the on board compressor. For more information see the PCM User Manual.

➠ D-Link DAP-1522 Rev B

The D-Link DAP-1522 Rev B robot radio is used to provide wireless communication functionality to the robot. The device can be configured as an Access Point for direct connection of a laptop for use at home. It can also be configured as a bridge for use on the field. For more information, see programming your radio for home use.

➠ 120A Circuit Breaker

The 120A Main Circuit Breaker serves two roles on the robot: the main robot power switch and a protection device for downstream robot wiring and components. The 120A circuit breaker is wired to the positive terminals of the robot battery and PDP.

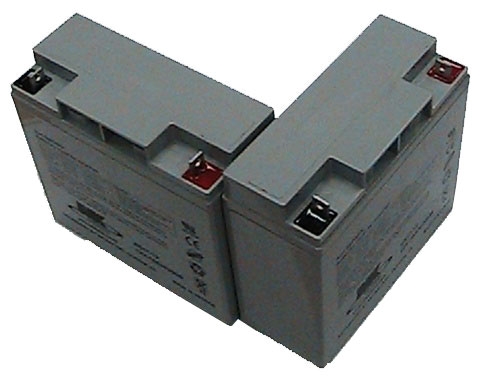

➠ Robot Battery

The power supply for an FRC robot is a single 12V 18Ah battery. The batteries used for FRC are sealed lead acid batteries capable of meeting the high current demands of an FRC robot. For more information, see the Datasheets for the MK ES17-12 and Enersys NP18-12. Note that other battery part numbers may be legal, consult the 2015 FRC Manual for a complete list.

➠ The motor controllers

In FRC robots (and most robots), you don't have access to the motor actuators directly. You need to wire your motor to a Talon, Jaguar or Victor controller to control it.

As of May 2015, the allowed motor controllers for FRC teams are:

The primary differences between the motor controllers above are:

- Safety: air intakes posses a serious security threat to your robot. Avoid them when possible.

- Size: depending on your robot, you may appreciate the smaller sized motor controllers.

- Output: each motor controller has a different way to control a motor. The best way to test this is by plugging in a motor and testing its performance with each controller.

- Temperature efficiency: older models, such as the Jaguar and Victor 888 controllers, may take more time to cool down than newer controllers.

Our team prefers to use the Victor SP controllers for secondary subsystems, such as the elevator or rollers. We use the Talon SRX controllers for primary subsystems, such as the drive system.